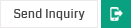

Jet Dyeing Machine

Product Details:

- Features Low liquor ratio, energy efficient, corrosion resistant, high automation, robust construction

- Weight 500-40000 Kilograms (kg)

- Type Jet Dyeing Machine

- Fabric width Up to 2400 mm Meter (m)

- Usage & Applications Dyeing of various fabrics including cotton, polyester, viscose, blended fabrics

- Capacity 50-3000 kg per batch Kg

- Machine Type Horizontal Cylindrical

- Click to View more

Jet Dyeing Machine Price And Quantity

- 500000 INR/Unit

- 1 Unit

Jet Dyeing Machine Product Specifications

- Low liquor ratio, energy efficient, corrosion resistant, high automation, robust construction

- 500-40000 Kilograms (kg)

- 50-3000 kg per batch Kg

- Dyeing of various fabrics including cotton, polyester, viscose, blended fabrics

- Up to 2400 mm Meter (m)

- Jet Dyeing Machine

- 220-440 Volt (v)

- Single/Multiple

- 500-30000 L Kilogram(Kg)

- 15-75 kW Statampere (sA)

- Horizontal Cylindrical

- Metal

- Room Temperature to 140C Rankine

- Woven, Knitted, Synthetic, Blended

- Automatic PLC Control

- 2023 Years

- Up to 350 RPM Km/hr

- Centrifugal Pump with Stainless Steel Impeller

- Customized Meter (m)

Jet Dyeing Machine Trade Information

- Cheque

- 3 Unit Per Month

- 2 Week

- South America, Africa, Middle East, Western Europe, Australia, Asia, Central America, Eastern Europe, North America

- All India

Product Description

had meeting done with karimbhai said that use it regular base and mark irrelevant inquiry had meeting done with karimbhai said that use it regular base and mark irrelevant inquiryWe are counted amongst the leading manufacturers, exporters and suppliers of excellent quality Jet Dyeing Machine that is widely used for heating which does not require any medium in dying machine. In order to meet the set industry norms, this machine is precisely engineered by our well-versed professionals by making use of quality assured raw material and modern technology. Also, this Jet Dyeing Machine can be availed from us in diverse specifications as per the clients' requirement.

In these Development, there is no fabric drive reel to move fabric. the fabric movement by only force of water. it is economical, because of low liqour ration its reduce every thing. it is user's friendly because of comparison with long tube dyeing machine, to control the fabric movement 4 valves required. here in this jet dyeing machines and fabric jet dyeing machine there is only one valve. absent of reel, reduce connecting electric power, maintenance of two mechanical seal and break down time, if jet pressure and reel speed not synchronized. nearly 4000 with out fabric drive reel machines are saving energy and reducing pollution in 23 countries of this planet.

Features:

- Higher storage capacity

- Excellent performance

- Longer service life

- Robust construction

Exclusive Features:

- Lowest Liquor ration

- Reduce power consumption

- Reduce thermic energy

- No fabric drive reel

- Reduce maintenance

- Lowest running cost

- Zero Entanglement

Technical Features:

- Capacity : 22 to 400Kg. (Single Tube)

- Ultra low liquor ratio- 1:1 (wet fabric)

- Dye - 30 To 450 Grms./Mtr. Sq. Fabrics (Woven & Knitted Fabrics)

- High Temp.- Up to 140 Deg C.

- Fabric Speed - 300 Mtrs./Min.

- Vessel: SS 316 L

Optional Features:

- Fully automatic with PLC.

- Main pump Invertor

- Sealless Pump

- Flow meter ( water liter counter)

- Seam detector

- Magnetic level indicator / Controller

- Double tube for higher capacity

Model:

This basket is using for store the fabrics.

Other development for increase the capacity instead of basket putting rods, which increase the capacity of machine in same total machine volume that reduces the running cost with comparison of with basket type machine.

Advanced Stainless Steel Construction

Manufactured with SS316/SS304 stainless steel for both inner and outer drums, this Jet Dyeing Machine ensures excellent resistance to corrosion and long-term operational reliability. These premium materials facilitate the dyeing of a wide range of fabrics, supporting extensive use in diverse environments and applications. The robust construction minimizes maintenance and guarantees optimal performance in demanding industrial settings.

Efficient and Versatile Operation

Thanks to a liquor ratio range of 1:4 to 1:6 and a high-speed operation up to 350 RPM, this machine ensures uniform dyeing while conserving resources. The automatic PLC-controlled dosing system and the option between steam or electric heating make it adaptable for different textiles and production scales. Noise levels remain below 75 dB, promoting a safer and more comfortable work environment.

Cutting-edge Automation and Safety

Automatic chemical dosing, over-pressure and over-temperature protection, and centrifugal pumps with stainless steel impellers streamline operation while safeguarding both materials and personnel. The customizable control and loading options further enhance usability, making the machine ideal for dealers, manufacturers, exporters, and other stakeholders in the textile industry.

FAQ's of Jet Dyeing Machine:

Q: How does the Jet Dyeing Machine ensure efficient energy usage during the dyeing process?

A: The machine operates on a low liquor ratio (1:4 to 1:6), utilizing less water and energy per batch. Additionally, the machine features energy-efficient steam or electric heating systems and robust insulation, all contributing to reduced operational costs and lower environmental impact.Q: What safety features are integrated into this Jet Dyeing Machine?

A: Key safety features include over-pressure and over-temperature protection mechanisms, automatic emergency shutdown, and PLC-controlled monitoring. These systems ensure safe operation, preventing accidents and equipment damage even under intense industrial use.Q: When should maintenance be performed on this Jet Dyeing Machine?

A: Routine maintenance is recommended after a set number of dyeing cycles, depending on usage intensity. Stainless steel construction helps minimize corrosion, but regular checks on seals, pumps, and control systems are essential to maintain efficiency and prevent unplanned downtime.Q: Where can this Jet Dyeing Machine be installed within a textile facility?

A: With a customizable footprint and dimension options, the machine can be installed in various manufacturing settings, from small workshops to large-scale textile plants. The horizontal cylindrical design and front or top loading enhance flexibility in space utilization.Q: What types of fabrics can be dyed using this Jet Dyeing Machine?

A: The machine is adept at processing woven, knitted, synthetic, and blended fabrics, including cotton, polyester, viscose, and other blends-making it especially versatile for textile manufacturers handling diverse material portfolios.Q: How does the automatic chemical dosing system work?

A: The automated dosing system precisely measures and injects chemicals at programmed intervals, controlled by the PLC. This not only ensures consistent dyeing results but also minimizes manual handling and improves operator safety.Q: What are the main benefits of using this Jet Dyeing Machine for textile processing?

A: Key benefits include high automation, superior corrosion resistance, efficient resource consumption, advanced safety features, and adaptability for multiple fabric types and batch sizes. This leads to increased productivity, product quality, and overall operational efficiency for textile businesses.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'Fabric Dyeing Machine' category

|

APEX ENGINEERS

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |