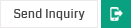

Rapid Jet Dyeing Machine

500000.00 - 5000000.00 INR

Product Details:

- Type Rapid Jet Dyeing Machine

- Machine Type Automatic Dyeing Machine

- Fabric Type Woven and knitted fabrics

- Temperature Range Up to 140C

- Pump Type Centrifugal High-pressure Pump

- Capacity 50-1200 kg per batch

- Speed Variable, up to 300 m/min

- Click to View more

X

Rapid Jet Dyeing Machine Price And Quantity

- 500000.00 - 5000000.00 INR

- 1 Unit

Rapid Jet Dyeing Machine Product Specifications

- Up to 2400 mm

- Variable, up to 300 m/min

- Low liquor ratio, energy-saving, high dye penetration, uniform color

- 500-50000 Kilograms (kg)

- 50-1200 kg per batch

- Up to 140C

- Centrifugal High-pressure Pump

- Rapid Jet Dyeing Machine

- Automatic Dyeing Machine

- Woven and knitted fabrics

- Textile dyeing, sample and bulk production

- 220-440 Volt (v)

- 500-12000 liters

- Cotton, Polyester, Blends, Silk, Viscose

- 2024

- Single/Multiple

- PLC Control

- 7.5-110 kW

- Custom, typically 4000x2200x3500 mm

Rapid Jet Dyeing Machine Trade Information

- Cheque

- 3-4 Unit Per Month

- 2 Week

- Western Europe, South America, Eastern Europe, Middle East, Central America, Africa, Australia, Asia, North America

- All India

Product Description

Rapid Jet Dyeing Machine

Our valuable clients can avail from us a wide assortment of Rapid Jet Dyeing Machine. This jet dyeing machine is used for heating which does not require any medium. Manufactured with the help of latest technology by utilizing quality approved raw material under the observation of our technical professionals, this machine is checked on various quality parameters by highly skilled experts. We offer this Rapid Jet Dyeing Machine in various specifications and at reasonable price.

Exclusive Features:

- Lowest liquor ratio compare to other long tube machine

- Reduce power consumption

- Reduce thermic energy

- Reduce maintenance

- Lowest running cost

Technical Features:

- Capacity : upto 400Kg ( Single Vessel)

- Dye - 30 To 450 Grms./Mtr. Sq. Fabrics (Woven & Knitted Fabrics)

- Liquor ratio: 1:4 to 1:5 (Wet fabric)

- High Temp. - Up to 140C

- Vessel made from - SS 316 L

- Single vessel two chamber to reduce the loop length as well as process time

- Inside PTFE sheet for antangle operation

- Online washing system

- Specially design bow jet nozzle for extra force

- Fabric drive reel with frequency controller

Optional Features:

- Fully automatic with PLC

- Main pump Inverter

- Flow meter (Water liter counter)

- Seam detector

- Magnetic level indicator / controller

- Double tube for higher capacity

Superior Construction and Compatibility

Constructed from premium SS304/SS316 stainless steel, the Rapid Jet Dyeing Machine offers long-term reliability and robust performance. It supports a variety of woven and knitted fabrics, with widths up to 2400 mm. Compatible materials include cotton, polyester, blends, silk, and viscose, making it versatile for both sample and large-scale textile production.

Efficient Dyeing Process with Advanced Features

The machine incorporates adjustable jet nozzles for precise fabric movement, resulting in high dye penetration and uniformity. Its low liquor ratio and efficient water circulation reduce consumption, while the energy-saving design minimizes operational costs. Electric or steam heating further optimizes the dyeing cycle, allowing for flexible process choices.

User-Friendly Automation and Maintenance

With PLC-controlled automation, the Rapid Jet Dyeing Machine allows for streamlined, fully-automated dyeing operations, including automatic chemical dosing. Maintenance is simplified through easy access points for cleaning and servicing. Noise levels are kept low (75 dB) to promote a comfortable working environment, while customizable exterior color options enhance integration with your facility.

FAQ's of Rapid Jet Dyeing Machine:

Q: How does the Rapid Jet Dyeing Machine maintain low water and energy consumption during operation?

A: The machine utilizes optimized circulating systems with low liquor ratios, adjustable high-pressure jet nozzles, and energy-efficient electric or steam heating, all contributing to minimized water and energy use while ensuring superior dye penetration and color consistency throughout each batch.Q: What is the process involved in dyeing fabrics with this machine?

A: Fabrics are loaded into the chamber, where adjustable velocity jet nozzles drive uniform dye liquor movement. The PLC system controls automatic dosing of chemicals, temperature regulation (up to 140C), and process speed. Once the dyeing cycle concludes, fabrics are easily accessed for unloading due to the user-friendly design.Q: What types of fabrics and materials can be dyed using this machine?

A: The Rapid Jet Dyeing Machine is suitable for a broad spectrum of woven and knitted fabrics, including cotton, polyester, silk, viscose, and their blends. Its adjustable features support fabric widths up to 2400 mm and batch capacities from 50 to 1200 kg.Q: What safety features are incorporated into the machine?

A: The machine is equipped with over-temperature protection, automatic pressure release mechanisms, and low-noise operation (75 dB) to ensure operator safety and prevent process interruptions.Q: When is it advisable to use this machine for textile manufacturing?

A: This machine is ideal for sample and large-scale batch dyeing processes in textile mills, particularly when high consistency, energy efficiency, and adaptability to diverse fabric types and colors are priorities. It is suitable for operation by manufacturers, exporters, and service providers.Q: What maintenance requirements should be considered during operation?

A: Routine maintenance is straightforward due to accessible cleaning and servicing points. Periodic checks of pumps, nozzles, and PLC control settings are recommended to ensure continued efficient and safe operation of the machine.Q: Where can the Rapid Jet Dyeing Machine be implemented and who can benefit from it?

A: The machine can be installed in textile facilities across India and is beneficial for manufacturers, distributors, exporters, retailers, and service providers in the textile industry seeking high productivity, reduced resource consumption, and consistent dyeing quality.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Fabric Dyeing Machine' category

|

APEX ENGINEERS

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |