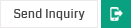

Conventional Rapid Jet Dyeing Machine

Product Details:

- Pump Type Centrifugal/Jet Pump

- Speed High

- Fabric Type Woven and Knitted

- Usage & Applications Industrial dyeing of polyester, cotton, blended, knitted and woven fabrics

- Volume 500-40000 L

- Type Conventional Rapid Jet Dyeing Machine

- Machine Type Jet Dyeing Machine

- Click to View more

Conventional Rapid Jet Dyeing Machine Price And Quantity

- 1 Unit

- 500000.00 - 5000000.00 INR

Conventional Rapid Jet Dyeing Machine Product Specifications

- Conventional Rapid Jet Dyeing Machine

- Jet Dyeing Machine

- Up to 2400 mm

- 5-75 kW

- 2024

- 500-40000 Kilograms (kg)

- Centrifugal/Jet Pump

- High

- Industrial dyeing of polyester, cotton, blended, knitted and woven fabrics

- Woven and Knitted

- 500-40000 L

- 50-2000 kg/batch

- Metal

- PLC/Automatic

- 220-440 Volt (v)

- Up to 140C

- Low liquor ratio, High efficiency, Robust construction, Automatic control panel

- Customized

- 2-8

Conventional Rapid Jet Dyeing Machine Trade Information

- 3-4 Unit Per Month

- 2 Week

- Western Europe, Australia, Eastern Europe, Middle East, Central America, Africa, South America, Asia, North America

- All India

Product Description

Vastly Improved Smother Running Condition

Dyeing of Micro fiber lower liquor ration (lower than 1.8) reducing of running coat and total water consumption with effluent treatment cost.

Running at stable, lower tension

No more clogging up in the back of the chamber at room temperature to get better result of Bo-finish & of shirting & suiting also.

Our latest design required slop on rear construction improves smother fabric transportation and stable loading condition to get tangle free operation during the low & high temporary Process.

Low liquor ration dyeing

More uniform circulation and better liquid better separating structure contributes to stable and lower tension running while process.

Exclusive Features:

- Lowest liquor ratio compare to other long tube machine

- Reduce power consumption

- Reduce thermic energy

- Reduce maintenance

- Lowest running cost

Technical Features:

- Capacity : 25 to 400Kg ( Single Vessel)

- Dye - 30 To 450 Grms./Mtr. Sq. Fabrics (Woven & Knitted Fabrics)

- Liquor ratio: 1:8 (Wet fabric)

- High Temp. - Up to 140C

- Vessel made from - SS 316 L

- Specially design bow jet nozzle for extra force.

- Fabric drive reel with frequency controller.

Optional Features:

- Fully automatic with PLC

- Main pump Inverter

- Flow meter (Water liter counter)

- Seam detector

- Magnetic level indicator / controller

- Double tube for higher capacity

Superior Material Construction

Engineered with premium Stainless Steel 316/304, the machine guarantees excellent resistance to corrosion and wear, making it suitable for long-term industrial use. This durability ensures consistent dyeing results while minimizing maintenance needs over time, further enhancing its appeal for manufacturers handling large batches and diverse fabric types.

Efficient Dyeing with Low Liquor Ratio

The machine operates at an impressively low liquor ratio of 1:3 to 1:5, leading to reduced water and energy consumption. This efficient system not only optimizes resource usage but also promotes eco-friendly operations, making it a smart investment for sustainability-focused textile producers.

Advanced Safety and Automation

Operators can rely on over-pressure and over-temperature protection for secure operation. The integrated PLC/automatic control panel, together with automatic dosing and drain systems, streamlines the dyeing process, minimizes human error, and supports consistent dye quality for every batch.

FAQ's of Conventional Rapid Jet Dyeing Machine:

Q: How does the Conventional Rapid Jet Dyeing Machine enhance dyeing efficiency?

A: By utilizing a low liquor ratio (1:3 to 1:5) and a high-speed processing system, the machine significantly reduces water, energy, and chemical consumption while maintaining high dye uniformity, making it perfect for large-scale industrial production.Q: What types of fabrics and batch sizes can be processed with this machine?

A: This machine is designed for both woven and knitted fabrics, including polyester, cotton, and blended materials, with a flexible batch capacity that ranges from 50 to 2000 kg per cycle, accommodating diverse production needs.Q: When is the integrated automatic color dosage system most beneficial?

A: The automatic color dosage system is particularly advantageous during large or frequent batch dyeing, as it ensures precise and consistent color mixing, reduces manual errors, and saves on dye costs.Q: Where can this dyeing machine be installed and utilized?

A: Thanks to its robust build and customizable dimensions, the jet dyeing machine can be installed in various industrial settings-including textile mills, processing plants, and dye houses-across India and beyond.Q: What is the process for operating the machine safely?

A: Operators use the PLC/automatic control panel to set parameters. The system's safety features-such as over-pressure and over-temperature protection-work automatically to prevent accidents, while the pneumatic/hydraulic door provides easy and secure access for fabric loading and unloading.Q: How does the automatic drain and low water consumption benefit users?

A: The automatic drain system ensures fast, effective removal of wastewater, reducing downtime and boosting productivity. Combined with the machine's low water consumption, this leads to lower operational costs and a smaller environmental footprint.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'Fabric Dyeing Machine' category

|

APEX ENGINEERS

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |