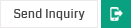

Open Width Cum Rope Multi Chamber Washing Range

1400000.00 - 3000000.00 INR/Set

Product Details:

- Type Other

- Material STAINLESS STEEL

- Power 10-50 Horsepower (HP)

- Power Source Electric

- Voltage 415 Volt (v)

- Automatic Grade Automatic

- Loading Type Other

- Click to View more

X

Open Width Cum Rope Multi Chamber Washing Range Price And Quantity

- 1 Set

- 1400000.00 - 3000000.00 INR/Set

Open Width Cum Rope Multi Chamber Washing Range Product Specifications

- Other

- 10-50 Horsepower (HP)

- Electric

- Other

- GREY

- STAINLESS STEEL

- 415 Volt (v)

- Automatic

- Other

Open Width Cum Rope Multi Chamber Washing Range Trade Information

- SACHIN

- Cheque

- 1 Set Per Month

- 45 Days

- Contact us for information regarding our sample policy

- PLASTIC WRAP

- All India

- ISO 9001:2015

Product Description

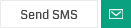

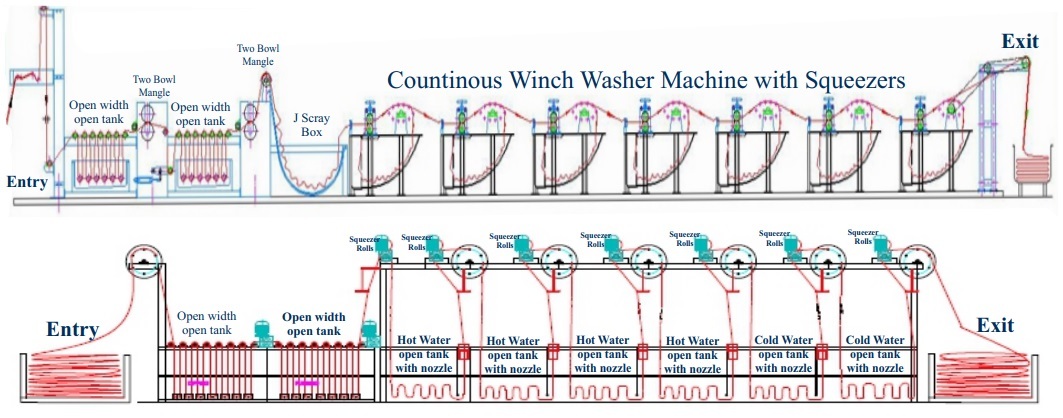

The range is useful for washing of rayon blendor knit fabrics. As rayon has very poor wet strength it is washed in ropeform. Knit fabrics tend to elongate inopen form and requires many holding gadgets so it is washed in rope form toavoid curling and elongation. The washing range has two nos. open widthcompartment for the purpose of wetting and swelling of dyes and gum paste. Thenthe fabric is accumulated in J scray prior to entering in to winch washingcompartments. The oval type s.s. winch helps in thrashing the fabric in to thes.s. wash tank to remove the gum andexcessive colour. There is a provision of heating the water with steam for faster removing of excessivematerials. The fabric content in each tank depends on the width of the tank,which is approx 110kg up to 200kg of fabric

Advanced Fabric Washing Technology

This multi chamber washing range leverages both open width and rope processing methods to accommodate various fabric types and washing requirements. The high-powered motor and automatic controls ensure uniform cleaning and minimize manual intervention, enhancing productivity for textile businesses.

Built for Industrial Excellence

Constructed using durable stainless steel, the machine withstands heavy-duty operations and resists corrosion, making it a long-lasting investment for textile units. Grey finish and modern design allow for seamless integration into contemporary production spaces while maintaining high hygiene standards.

FAQ's of Open Width Cum Rope Multi Chamber Washing Range:

Q: How does the Open Width Cum Rope Multi Chamber Washing Range operate?

A: The machine functions automatically, utilizing a 415 Volt electric power source and a robust motor rated between 10 to 50 HP. It washes fabrics either in open width or rope form through multiple chambers, providing efficient and thorough cleaning.Q: What types of fabrics can be processed in this washing range?

A: This washing system is versatile and suitable for a variety of textile materials, including cotton, synthetics, and blends. It can handle both open width and rope fabric formats, enabling flexibility in industrial processing.Q: When should this washing range be used?

A: It is ideal for use during the primary washing phase of textile production, especially in large-scale operations where efficiency and consistency are critical. Companies requiring high throughput and minimal manual handling benefit most from its automatic features.Q: Where is the Open Width Cum Rope Multi Chamber Washing Range manufactured and supplied?

A: This machine is manufactured in India and distributed nationwide. It is available through a network of dealers, distributors, exporters, fabricators, importers, manufacturers, retailers, service providers, suppliers, traders, and wholesalers.Q: What is the process involved in washing textiles using this equipment?

A: Textiles are fed either as open width or rope into the machine, passing through multiple chambers where automatic washing, rinsing, and finishing take place. The system ensures even exposure to detergents and water, resulting in consistent cleanliness.Q: What are the key benefits of using this automatic washing range?

A: The main benefits include increased washing efficiency, reduced labor costs, uniform results, and compatibility with various fabric types. Its stainless steel construction also guarantees durability and easy maintenance for prolonged use.Q: How is the machine maintained to ensure optimal performance?

A: Routine inspection, regular cleaning, and adherence to the manufacturer's guidelines help maintain the equipment. Stainless steel material makes maintenance straightforward, as it resists rust and chemical damage from detergents.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

|

APEX ENGINEERS

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |