Multi Nozzle Soft Flow Dyeing Machines

Product Details:

- No Of Chamber 2-8

- Pump Type Centrifugal Stainless Steel

- Dimension (L*W*H) 4800 x 2200 x 2100 mm

- Weight Approx. 2500 kg

- Usage & Applications Textile dyeing, fabric processing, sample and bulk dyeing

- Fabric Type Woven, Knitted, Synthetic, Cotton

- Voltage 220-440 Volt (v)

- Click to View more

Multi Nozzle Soft Flow Dyeing Machines Price And Quantity

- 1 Unit

- 500000.00 - 5000000.00 INR/Set

Multi Nozzle Soft Flow Dyeing Machines Product Specifications

- Metal

- Multi-nozzle system, low liquor ratio, gentle fabric handling, high efficiency, automatic dosing, integrated safety system

- Automatic

- Up to 2400 mm

- Room Temp to 140C

- PLC / Digital Controller

- 2000-8000 Liters

- Multi Nozzle Soft Flow Dyeing Machines

- 15-25 kW

- Woven, Knitted, Synthetic, Cotton

- Textile dyeing, fabric processing, sample and bulk dyeing

- 2024

- 200-3300 RPM

- 220-440 Volt (v)

- 300-1200 kg/batch

- 2-8

- Centrifugal Stainless Steel

- 4800 x 2200 x 2100 mm

- Approx. 2500 kg

Multi Nozzle Soft Flow Dyeing Machines Trade Information

- Cheque

- 3 Unit Per Month

- 2 Week

- Western Europe, Australia, Eastern Europe, Middle East, Central America, Africa, South America, Asia, North America

- All India

Product Description

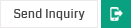

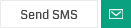

ECONOMICAL MULTI NOZZLE SOFT/JET DYEING MACHINE

Bhagyarekha's new textile and fabric dyeing plant has penetrated internationally dye-house machinery market with its new multi-nozzle soft flow dyeing machines that offers high productivity with low liquor ratio in fabric dyeing compared to the conventional dyeing machinery.

Bhagyarekha's multi-nozzle soft flow dyeing machinery is the new age solution. The Bhagyarekha Multi-Nozzle Low/High Temperature Dyeing technology works as soft flow as well as jet dyeing machine. The main advantage of this development is to increase the machine flexibility / versatility, to process all types of fabrics.

In this new technical development, the soft-nozzles have big diameter and fix nozzle has an individual flow control valve. The main nozzle is adjustable. By increasing and decreasing the gap of nozzle, flow and pressure increases and decreases as per fabric quality demand. To run this machine as a soft flow machine, increase the gap that decreases the pressure and increases water flow. At that time all three nozzles work as soft flow and water flow gets control individually by control valve as per fabric quality demand.

To run machine as a jet dyeing machine, decrease the gap of nozzle, that increases the pressure and decreases the water flow. That time close the soft-nozzle control valve.

Exclusive Features:

- Lowest Liquor ration

- Reduce power consumption

- Reduce thermic energy

- Reduce maintenance

- Lowest running cost

- Zero Entanglement

- No pilling effect

- Suitable for nearly all types of fabric quality

Technical Features:

- Capacity : 25 to 400Kg. (Single Tube)

- Ultra low liquor ratio- 1:1 (wet fabric)

- Dye - 30 To 500 Grms./Mtr. Sq. Fabrics (Woven & Knitted Fabrics)

- High Temp.- Up to 140 Deg C.

- Fabric Speed - 400 Mtrs./Min.

- Work as a jet dyeing as well soft flow to meet the requirements the requirements of all types of fabrics quality.

- Vessel: SS 316 L

- Numbers of very soft nozzles.

Optional Features:

- Fully automatic with PLC.

- Main pump Invertor

- Sealless Pump.

- Flow meter ( water liter counter)

- Seam detector

Innovative Multi-Nozzle Technology

This dyeing machine incorporates a multi-nozzle soft flow system, ensuring even dye penetration and superior fabric care. Its gentle circulation process is ideal for delicate and heavy fabrics, effectively minimizing fabric stress during dyeing. Automated and manual color dosing options further enhance dyeing precision and versatility, adjusting easily to different textile requirements.

Designed for Efficiency & Safety

Built with high-quality stainless steel and equipped with safety features like pressure release valves and overload protection, this machine supports robust, long-term use. Its low water and energy consumption, coupled with rapid batch processing capability, make it an eco-friendly and cost-effective solution for textile manufacturers.

User-Friendly Operation & Low Maintenance

With its touch screen HMI and digital PLC controller, the machine offers straightforward and customizable operation. Components are easily accessible for cleaning, ensuring minimal maintenance downtime. The modular design supports seamless integration into existing facilities, adapting efficiently across production scales.

FAQ's of Multi Nozzle Soft Flow Dyeing Machines:

Q: How does the multi-nozzle system benefit fabric dyeing?

A: The multi-nozzle system provides uniform dye distribution and gentle fabric movement, which reduces fabric stress and enhances consistent dye results. This design is especially beneficial for processing delicate woven, knitted, synthetic, and cotton fabrics.Q: What safety features are included in the machine?

A: The machine is equipped with a pressure release valve, emergency stop button, and overload protection, ensuring operator safety and secure operation during high-pressure or emergency situations.Q: What is the typical water consumption compared to conventional dyeing machines?

A: Thanks to its low liquor ratio and efficient flow design, this machine significantly reduces water consumption by minimizing dye bath volume, making it more environmentally friendly and cost-effective than traditional models.Q: Where can the Multi Nozzle Soft Flow Dyeing Machine be installed?

A: The machine supports flexible installation, either on-site or in a modular configuration, allowing easy adaptation to various textile production environments and integration with existing systems.Q: What is the recommended process for using the color dosage system?

A: Operators can choose between automatic or manual dosing. The automatic system precisely measures and dispenses dyes according to programmed recipes, while the manual mode allows for operator adjustments, ensuring flexibility for sample and bulk dyeing.Q: How easy is it to clean and maintain the machine?

A: Designed for low maintenance, the machine features easily accessible components, allowing quick and effective cleaning between dye batches. This reduces operational downtime and extends the equipment's lifespan.Q: What fabric types and sizes can be processed with this machine?

A: The machine is adaptable for a wide range of fabric types-woven, knitted, synthetic, and cotton-with fabric widths up to 2400 mm and batch capacities ranging from 300 to 1200 kg.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'Fabric Dyeing Machine' category

|

APEX ENGINEERS

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |