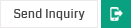

Beam Dyeing Machine

500000.00 - 5000000.00 INR

Product Details:

- Applicable Material Metal

- Usage & Applications Textile dyeing, Yarn dyeing, Knitwear & Woven Fabric Processing

- Pump Type High Efficiency Centrifugal Pump

- Capacity 300-5000 kg per batch

- Dimension (L*W*H) Customizable, e.g., 3500 x 1800 x 2300 mm

- Machine Type Automatic

- Speed Variable, up to 1200 RPM

- Click to View more

X

Beam Dyeing Machine Price And Quantity

- 1 Unit

- 500000.00 - 5000000.00 INR

Beam Dyeing Machine Product Specifications

- Low Liquor Ratio, High Efficiency, Energy Saving, Robust Construction, Gentle Fabric Handling, Easy Operation, Corrosion Resistant

- Up to 140C

- Variable, standard 500-5000 L

- 2023

- Beam Dyeing Machine

- Up to 3200 mm

- PLC Control with HMI

- 500-40000 Kilograms (kg)

- Cotton, Polyester, Blended, Silk, Denims

- 15-50 kW

- 300-5000 kg per batch

- High Efficiency Centrifugal Pump

- Metal

- Textile dyeing, Yarn dyeing, Knitwear & Woven Fabric Processing

- 1 or 2 (customized)

- Variable, up to 1200 RPM

- 220-440 Volt (v)

- Automatic

- Customizable, e.g., 3500 x 1800 x 2300 mm

Beam Dyeing Machine Trade Information

- 3-4 Unit Per Month

- 2 Week

- Western Europe, Australia, Eastern Europe, Middle East, Central America, Africa, South America, Asia, North America

- All India

Product Description

We are an unparalleled name, engaged in offering a premium quality range of Beam Dyeing Machine that is used for dyeing and bleaching woven & knit fabrics in open width. Offered machine is precisely manufactured using best-in-class raw material and sophisticated technology. The offered machine is available in different specific options as per the varied needs of the clients. Extensively demanded in textile industry for its excellent performance, we offer this Beam Dyeing Machine at industry leading rates.

Features:

- Sturdy construction

- Excellent functionality

- User friendly design

- Trouble-free operation

Exclusive Features:

- Lowest liquor ratio.

- Reduce power consumption

- Reduce thermic energy

- Reduce maintenance

- Lowest running cost

Technical Features:

- Capacity : 100 to 200Kg

- High temp. Up to 140° C.

- Process woven & knitted fabrics in open width.

- Beam: Dia 300 mm * 1800 mm Long.

- Sampling Device.

- Dual head design, Multi flow, high pressure centrifugal pump of dye- liquor in & out circulation.

- Vessel made from - SS 316 L

Optional Features:

- Fully automatic with PLC. Main Pump Invertor. Flow Meter (water Liter Counter)

Superior Engineering for Versatile Applications

The Beam Dyeing Machine is tailored for yarn, knitwear, and woven fabric processing-delivering reliable and gentle handling for fabrics up to 3200 mm wide. Its AISI 304/316 stainless steel build and high-density thermal insulation deliver energy efficiency and durability, while the variable speed up to 1200 RPM adapts seamlessly to diverse production demands, ensuring consistent dye penetration and quality results.

User-Friendly Automation and Safety

Equipped with PLC control, HMI interface, and automatic proportional dosing, the machine prioritizes operator ease and precision. Its built-in safety features-including overpressure and over-temperature protection and emergency stop-ensure a secure work environment. Robust construction and low liquor ratio further optimize operation efficiency and reduce resource consumption.

Versatile Compatibility and Maintenance

This machine supports disperse, reactive, direct, and vat dyes, making it ideal for a broad spectrum of textiles: cotton, polyester, denims, blends, and silk. Automatic Clean-in-Place (CIP) systems streamline maintenance and minimize downtime, promoting consistent hygiene and extending equipment lifespan. Customizable dimensions and capacity ensure suitability for various scales of textile operations.

FAQ's of Beam Dyeing Machine:

Q: How does the Beam Dyeing Machine ensure uniform dyeing across different fabrics?

A: The machine uses automated proportional dosing and a high-efficiency centrifugal pump to maintain uniform liquor circulation. With its integrated high-flow water system and variable speed control (up to 1200 RPM), it delivers consistent dye penetration in cotton, polyester, silk, blends, and denims, regardless of fabric width or batch size.Q: What safety mechanisms are incorporated in this machine's operation?

A: Safety is ensured through robust overpressure and over-temperature protection, as well as an emergency stop system. These features monitor critical parameters in real-time and immediately shut down the machine if abnormal conditions arise, safeguarding both operators and materials.Q: When should the automatic CIP (Clean-in-Place) system be used?

A: The automatic CIP system should be engaged after each dyeing batch or as recommended by the maintenance schedule. This system efficiently cleans internal pipelines and chambers, minimizing manual intervention and ensuring hygienic operation for subsequent dyeing processes.Q: Where can this Beam Dyeing Machine be installed and which role does its design play?

A: Designed for floor-mounted installation, the machine is suited for textile factories, dye houses, and processing units. Its customizable dimensions and sturdy construction adapt to varied production environments, providing flexibility for manufacturers, exporters, and service providers in the textile sector.Q: What is the process for changing between different dye types or colors?

A: The automatic CIP system thoroughly cleans the dyeing chambers and pipelines between batches, allowing quick and contamination-free transitions between disperse, reactive, direct, or vat dyes. Coupled with the PLC-controlled interface, operators can seamlessly set new parameters for each dye recipe.Q: How does using this machine benefit textile manufacturers?

A: Manufacturers gain advantages in energy efficiency, reduced liquor ratio, robust corrosion resistance, and gentle fabric handling. The integration of advanced automation, safety features, and comprehensive fabric compatibility increases productivity, lowers operational costs, and assures consistent dye quality across a variety of textile products.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Fabric Dyeing Machine' category

|

APEX ENGINEERS

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |