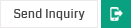

HTHP Soft Flow Dyeing Machine

Product Details:

- Fabric Type All textile fabrics (cotton, polyester, viscose, blends)

- Control Type PLC controlled, touch-screen interface

- Usage & Applications Dyeing of knit, woven and delicate fabrics in textile finishing

- No Of Chamber 1 to 6

- Weight 500-20000 Kilograms (kg)

- Speed Variable

- Fabric width Up to 2200 mm

- Click to View more

HTHP Soft Flow Dyeing Machine Price And Quantity

- 1 Unit

- 500000.00 - 5000000.00 INR

HTHP Soft Flow Dyeing Machine Product Specifications

- Metal

- 50 kg to 2000 kg per batch

- Variable

- Up to 2200 mm

- 500-20000 Kilograms (kg)

- 1 to 6

- All textile fabrics (cotton, polyester, viscose, blends)

- PLC controlled, touch-screen interface

- Dyeing of knit, woven and delicate fabrics in textile finishing

- 2024

- High efficiency centrifugal pump

- 250 L to 14000 L

- 220-440 Volt (v)

- HTHP Soft Flow Dyeing Machine

- Room temp to 140C

- Custom as per capacity (e.g., 6m x 2m x 2.5m)

- Soft Flow Dyeing

- 15-50 kW

- Low liquor ratio (1:4-1:6), energy efficient, automatic dosing, user-friendly interface

HTHP Soft Flow Dyeing Machine Trade Information

- 3-4 Unit Per Month

- 2 Week

- Western Europe, Australia, South America, Eastern Europe, Middle East, Central America, Africa, Asia, North America

- All India

Product Description

ECONOMICAL HT. HP. SOFT FLOW DYEING MACHINE.

Ht. Hp. Soft dyeing machine is suitable for the sensitive surface sturcture natural fabrics, such as cotton wool, viscose, acrylic and their blends of jersey, terry towel, velour and nylon.

It has been built with modern technology of high liquor flow using curved nozzle, which is transfer the fabrics very smoothly and minimized the tension and avoid crease and peeling.

Exclusive Features:

· Lowest liquor ratio up to 1:5 (wet fabrics)

· Reduce power consumption

· Reduce thermic energy

· Reduce maintenance

· Lowest running cost

· Tangle free operation.

· Online washing system to save the time.

· No rope marks, no pilling effect, no hairiness.

Standard Features:

· Dye 30 to 450 g./mt.sq. Fabric (cotton woven, cotton knit and its blends)

· Cup type very soft flow nozzle with low pressure higher flow design.

· Online filter design for easy cleanup even during the process with extra replaceable filter mesh.

· Specially design vessel cleaning system by SS spraying nozzles.

· Fabric drive reel with A.C. Motor & Frequency controller.

· S.S. Control Panel with rotary switch, Emergency stop, Fabric speed indicator, Hotter & moderate operation panel.

· PTFE sheet in basket.

· Vessel made from AISI SS 316 L.

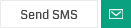

Technical Data:

· Capacity - 25kg. to 2000kg.

· Dye - 30 To 500 Grms./Mtr. Sq. Fabrics (Woven & Knitted Fabrics)

· High Temp.- Up to 140 Deg C.

· Vessel: SS 316 L

· Online filter design for easy cleanup even during the process with extra replaceable filter mesh.

· Sheet inside the chamber for smooth fabrics movement.

· Cup type very soft flow nozzle with low pressure higher volume design.

· Fabric drive reel with Frequency controller

Optional Features:

· Fully automatic with PLC.

· Main pump Invertor

· Sealless Pump.

· Flow meter ( water liter counter)

· Seam detector

· Magnetic level indicator / Controller

Advanced Process Automation

Equipped with a user-friendly PLC control system and touch-screen interface, this dyeing machine streamlines operation. Automatic recipe management and chemical dosing ensure consistent dyeing results while simplifying workflow, reducing operational errors, and supporting both manual and automatic dosing options.

Exceptional Energy and Water Efficiency

Designed with a low liquor ratio of 1:4-1:6, the HTHP Soft Flow Dyeing Machine minimizes water and energy consumption. High-efficiency centrifugal pumps, optimized water circulation, and integrated cooling systems contribute to cost savings and reduced environmental impact during operation.

Comprehensive Safety and Compliance

Safety is guaranteed with automatic pressure release valves, over-temperature cut-offs, and a leak-proof hydraulically operated door. The machine is both CE and ISO 9001 certified, offering assured safety and quality standards, making it suitable for international markets.

FAQ's of HTHP Soft Flow Dyeing Machine:

Q: How does the HTHP Soft Flow Dyeing Machine enhance dyeing efficiency for textile fabrics?

A: The machine utilizes a low liquor ratio (1:4-1:6) and high-efficiency centrifugal pumps, enabling rapid dye penetration and uniform color distribution while reducing water and energy consumption. Its process automation, including programmable chemical dosing and recipe management, ensures repeatable, high-quality results with minimal manual intervention.Q: What safety features are integrated into the HTHP Soft Flow Dyeing Machine?

A: Key safety features include an automatic pressure release valve, over-temperature cut-off system, and a hydraulically operated leak-proof door. These measures, combined with matte or mirror finish stainless steel construction, ensure operator safety and reliable containment of processing conditions during operation.Q: When is maintenance recommended, and how is it facilitated?

A: Routine maintenance should follow the manufacturer's guidelines or after every major batch cycle. The design incorporates easy access panels and CIP (Clean-In-Place) compatibility, which simplify cleaning and servicing, help minimize downtime, and keep the machine running efficiently.Q: Where can the HTHP Soft Flow Dyeing Machine be installed, and is technical support available?

A: The machine can be installed in textile processing units, manufacturing plants, or dye houses wherever high-performance dyeing is required. On-site technical support is provided during installation, ensuring correct setup and smooth integration into existing production lines.Q: What textile fabrics and capacities does the machine support?

A: This dyeing machine is suitable for all kinds of textile fabrics-knit, woven, and delicate materials such as cotton, polyester, viscose, and blends. It accommodates custom batch capacities ranging from 50 kg to 2000 kg, with a width capability of up to 2200 mm and multiple chamber options.Q: How does the product benefit textile manufacturers and exporters?

A: The HTHP Soft Flow Dyeing Machine offers minimized resource usage, consistent product quality, automated controls, and compliance with international standards. These factors result in lower operational costs, reduced environmental impact, and enhanced competitiveness for manufacturers and exporters in India's textile sector.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'Fabric Dyeing Machine' category

|

APEX ENGINEERS

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |