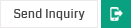

Top Tube Soft Flow Dyeing Machine

500000.00 - 5000000.00 INR

Product Details:

- Fabric Type Knitted, woven and synthetic fabrics

- Pump Type Centrifugal Pump

- Weight 500-40000 Kilograms (kg)

- Control Type PLC/Manual

- Volume 500 L to 40,000 L

- Dimension (L*W*H) Customizable as per capacity

- Voltage 220-440 Volt (v)

- Click to View more

X

Top Tube Soft Flow Dyeing Machine Price And Quantity

- 500000.00 - 5000000.00 INR

- 1 Unit

Top Tube Soft Flow Dyeing Machine Product Specifications

- Knitted, woven and synthetic fabrics

- Centrifugal Pump

- 500-40000 Kilograms (kg)

- PLC/Manual

- 500 L to 40,000 L

- Customizable as per capacity

- 5-75 kW

- 220-440 Volt (v)

- Top Tube Soft Flow Dyeing Machine

- Metal

- Single/Multiple (as per model)

- Automatic, Semi-automatic

- 2024

- Variable speed control

- Up to 140C

- 50 kg to 2000 kg per batch

- 50-3000 mm

- Low liquor ratio, high efficiency, user-friendly interface, stainless steel construction

- Dyeing and processing of tubular textiles in textile industries

Top Tube Soft Flow Dyeing Machine Trade Information

- 3-4 Unit Per Month

- 2 Week

- Western Europe, Middle East, Central America, Africa, South America, Australia, Asia, Eastern Europe, North America

- All India

Product Description

With our rich industry experience and knowledge, we are engaged in offering high quality Top Tube Soft Flow Dyeing Machine. This dyeing machine is suitable for processing knitted fabrics & sanative woven. Offered dyeing machine is manufactured under the guidance of our proficient experts using quality assured raw material with the help of latest technology to ensure its optimum functionality at users' end. We are offering this Top Tube Soft Flow Dyeing Machine at market leading price to our clients.

Features:

- Sturdy construction

- Compact design

- Less energy consumption

- Longer service life

Exclusive Features:

- Lowest liquor ratio compare to other long tube machine

- Reduce power consumption

- Reduce thermic energy

- Reduce maintenance

- Lowest running cost

Technical Features:

- Capacity : 100 to 350Kg

- Single vessel two chamber to reduce the loop length.

- Dye - 30 To 450 Grms./Mtr. Sq. Fabrics (Woven & Knitted Fabrics)

- Liquor ratio: 1:8 (Wet fabric)

- High Temp. - Up to 140°C

- Vessel made from - SS 316 L

- Specially design soft nozzle for smooth and entangle free operation.

- Fabric drive reel with frequency controller.

Optional Features:

- Fully automatic with PLC

- Main pump Inverter

- Flow meter (Water liter counter)

- Seam detector

- Magnetic level indicator / controller

- Double tube for higher capacity.

Advanced Safety and Control

Safety is paramount in the Top Tube Soft Flow Dyeing Machine, featuring automatic pressure and temperature cut-off systems, an emergency valve, and a leak-proof door design. Operators benefit from intuitive touchscreen controls with real-time process monitoring and seamless adjustment via PLC or manual modes.

Superior Efficiency & Versatility

Engineered with optimized water consumption and a low liquor ratio, this dyeing machine ensures economic operation with minimal environmental impact. Its automatic chemical dosing and variable speed allow precise process adaptability for various fabric types and widths.

Robust Construction & Customization

Built with SS 304/316 stainless steel, the machine stands out for its longevity and resistance to harsh chemicals. Customizable dimensions, capacity, color, and batch size ensure it fits seamlessly into facilities of any scale. Electric or steam heating options provide operational flexibility.

FAQ's of Top Tube Soft Flow Dyeing Machine:

Q: How does the automatic chemical dosing system enhance the dyeing process?

A: The automatic chemical dosing system ensures precise and consistent introduction of chemicals during each cycle, leading to uniform dyeing, improved color accuracy, and reduced manual labor. This feature also optimizes process efficiency and minimizes chemical wastage.Q: What fabrics and textile types are compatible with the Top Tube Soft Flow Dyeing Machine?

A: This machine is suitable for a wide variety of materials, including knitted, woven, and synthetic fabrics with widths ranging from 50 mm to 3000 mm. Its gentle flow mechanism minimizes fabric tension, making it ideal for tubular textile applications.Q: Where is the Top Tube Soft Flow Dyeing Machine typically used?

A: The machine is primarily used in textile industries by manufacturers, exporters, service providers, and fabricators for dyeing and processing tubular fabrics. It suits both small workshops and large manufacturing units across India and globally.Q: What safety features are integrated into this dyeing machine?

A: For operator safety, the machine includes automatic pressure and temperature cut-off systems, an emergency valve, leak-proof doors with easy locking mechanisms, and thermal insulation to prevent accidents and ensure stable operation.Q: How is water consumption optimized in this machine?

A: The machine's low liquor ratio and advanced flow design significantly reduce water usage, ensuring sustainable operations. Efficient pump technology and variable speed control further optimize water consumption for different batch sizes.Q: When should I use electric heating versus steam heating?

A: Electric heating is ideal when precise temperature control and flexibility are required, especially in facilities without central steam supply. Steam heating is preferable for larger operations with existing steam infrastructure seeking faster heat-up times and energy efficiency.Q: What are the control options available and how do they benefit the user?

A: Operators can choose between advanced PLC-based control with touchscreen interfaces or manual control panels. PLC control enables programmed process automation, real-time monitoring, and enhanced reproducibility, while manual control provides straightforward operation as needed.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Fabric Dyeing Machine' category

|

APEX ENGINEERS

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |