Fabric Weight Reduction Machine ( SOFTLEENA)

500000.00 - 5000000.00 INR

Product Details:

- Voltage 220-440 Volt (v)

- Volume 60-600 L

- Applicable Material Metal

- Fabric width 1500-3600 mm

- Temperature Range Up to 98C

- Power 18-42 kW

- Weight 500-40000 Kilograms (kg)

- Click to View more

X

Fabric Weight Reduction Machine ( SOFTLEENA) Price And Quantity

- 1 Unit

- 500000.00 - 5000000.00 INR

Fabric Weight Reduction Machine ( SOFTLEENA) Product Specifications

- 2023

- 200-1000 kg/h

- Variable, up to 60 m/min

- 2-6 Chambers

- Centrifugal / Magnetic drive

- PLC with HMI

- Automatic

- High Efficiency, Low Chemical Consumption, Eco-Friendly Design, Stainless Steel Construction, Adjustable Fabric Tension, Energy Saving

- 4300 x 3800 x 3300 mm

- Fabric Weight Reduction, Shrinkage Control, Surface Modification in Textile Processing

- Fabric Weight Reduction Machine

- Knitted & Woven Fabrics

- Metal

- 1500-3600 mm

- 18-42 kW

- Up to 98C

- 500-40000 Kilograms (kg)

- 60-600 L

- 220-440 Volt (v)

Fabric Weight Reduction Machine ( SOFTLEENA) Trade Information

- Cheque

- 3-4 Unit Unit Per Month

- 2 Week

- Western Europe, Australia, Eastern Europe, Middle East, Central America, Africa, South America, Asia, North America

- All India

Product Description

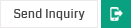

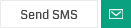

We have emerged as a leading manufacturer, exporter and supplier of superior quality Fabric Weight Reduction Machine. It is ideal for dyeing as well as weight reduction for synthetic fabric. Fabrics are circulated with low tension by alkali liquid sprayed from soft nozzle which gives good feet result improves the evenness of the fabric. Manufactured in conformity with international quality standards, this machine is made using the finest quality raw material and advanced technology. Offered Fabric Weight Reduction Machine can get from us at rock bottom rate.

Features:

- Low power consumption

- Longer service life

- Excellent performance

- Robust construction

Exclusive Features:

- Lowest liquor ratio.

- Reduce power consumption

- Reduce thermic energy

- Reduce maintenance

- Lowest running cost

- Zero Entanglement.

- Fully Dismantle design.

Technical Features:

- Capacity : 150 to 1000Kg

- Suitable to for dyeing as well as weight reduction for synthetic fabrics.

- Max. Temp.: Up to (98 Cel)

- Vessel made from - SS 316 L

- Caustic Recovery tank with pump & other accessories.

- Sampling Device.

Optional Features:

- Fully automatic with PLC.

- Partly Automatic.

- Main pump Inverter

- Flow meter (Water liter counter)

- Seam detector

- Magnetic level indicator / controller.

- Pre-heating System for recovery tank.

- Double tube for higher capacity.

Advanced Fabric Processing Technology

SOFTLEENA incorporates the latest engineering for fabric weight reduction, shrinkage control, and surface modification. Designed for high efficiency and minimal chemical usage, it ensures consistent results across a broad range of textile materials. The automated PLC with HMI enhances process control and monitoring, delivering superior fabric finishing every cycle.

Robust and Eco-Friendly Construction

Built with premium stainless steel and incorporating rubber or stainless steel rollers, SOFTLEENA assures durability while supporting eco-friendly practices. Its low energy and water requirements, combined with adjustable fabric tension and efficient chemical dosing, reduce operational costs and environmental impact.

Comprehensive Support and Versatility

Available to dealers, exporters, producers, and service providers in India, SOFTLEENA is backed by on-site commissioning and technical support. Its adaptability to various fabric types, chamber configurations, and control systems makes it ideal for diverse textile manufacturing needs.

FAQs of Fabric Weight Reduction Machine ( SOFTLEENA):

Q: How does the SOFTLEENA Fabric Weight Reduction Machine process textiles?

A: SOFTLEENA utilizes controlled steam or electric heating, fully automatic chemical dosing, and adjustable roller pressure to uniformly reduce fabric weight. Its variable speed and PLC-controlled operation ensure precise treatment for both knitted and woven fabrics, enhancing surface quality and maintaining fabric integrity.Q: What safety features are equipped in the SOFTLEENA machine?

A: The machine features comprehensive safety systems including overload and overheat protection, emergency stop functionality, and robust electrical safety standards. These systems safeguard both operators and equipment during high-capacity operations.Q: When should the SOFTLEENA machine be used in textile production?

A: It is best utilized during the textile finishing stage, particularly for applications requiring weight reduction, shrinkage control, or surface modification. The advanced control systems enable integration into modern, automated production lines.Q: Where can SOFTLEENA be installed, and what support is provided?

A: SOFTLEENA is available throughout India with on-site commissioning and installation support. Users receive guidance on setup, operator training, and ongoing technical assistance to maximize productivity and machine longevity.Q: What are the key benefits of using this fabric weight reduction machine?

A: Major advantages include high processing efficiency, low chemical and water consumption, eco-friendly design, reduced operating costs, and reliable results across diverse fabric types. The fully automatic operation and energy-saving features further enhance its value in textile production.Q: How does the PLC with HMI control improve the process?

A: The integrated PLC with HMI allows operators to easily monitor and adjust machine settings, such as temperature, speed, and chemical dosing. This results in higher precision, process repeatability, and consistently high fabric quality outcomes.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Fabric Dyeing Machine' category

|

APEX ENGINEERS

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |