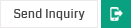

Atmospheric Soft Flow Dyeing Machines

Product Details:

- Power 7.5 50 kW

- Fabric width Up to 2400 mm

- Capacity Up to 600 kg per batch

- Type Atmospheric Soft Flow Dyeing Machines

- Features Low liquor ratio, energy efficient, easy operation, PLC control panel, auto dosing

- Usage & Applications Dyeing, scouring, bleaching and washing of knit and woven fabrics

- Weight 500-40000 Kilograms (kg)

- Click to View more

Atmospheric Soft Flow Dyeing Machines Price And Quantity

- 500000.00 - 5000000.00 INR/Unit

- 1 Unit

Atmospheric Soft Flow Dyeing Machines Product Specifications

- Atmospheric Soft Flow Dyeing Machines

- Low liquor ratio, energy efficient, easy operation, PLC control panel, auto dosing

- Up to 600 kg per batch

- Up to 2400 mm

- 7.5 50 kW

- 2200-440 Volt (v)

- 500-40000 Kilograms (kg)

- Dyeing, scouring, bleaching and washing of knit and woven fabrics

- Metal

- Varies with model (approx. 500 40000 L)

- Automatic

- 2024

- Single/Double/Multiple

- Centrifugal, Stainless Steel

- Customized as per model

- PLC/Automatic/Digital

- Woven and knitted fabrics

- Adjustable

- Ambient to 98C

Atmospheric Soft Flow Dyeing Machines Trade Information

- Cheque

- 3-4 Unit Unit Per Month

- 2 Week

- Western Europe, Australia, Middle East, Central America, Africa, South America, Asia, Eastern Europe, North America

- All India

Product Description

Atmospheric Soft Flow Dyeing Machines

Atmospheric soft flow dyeing machine is same machine like Ht. Hp. Soft flow dyeing machine. The only major difference is this machine work of low temperature pressure.

Some of the fabrics & some of the process did not require the high temperature process. for that, these machines is very much suitable because its reduce the running cost by saving energy. Also the liquor ration of these atmospheric machines is less than the Ht. Hp. soft flow machine, because of its "U" shape design.

Exclusive Features:

Technical Data:

AA Capacity - 25kg. to 2000kg.

AA Dye - 30 To 500 Grms./Mtr. Sq. Fabrics (Woven & Knitted Fabrics)

AA High Temp.- Up to 140 Deg C.

AA Vessel: SS 316 L

AA Online filter design for easy cleanup even during the process with extra replaceable filter mesh.

AA Sheet inside the chamber for smooth fabrics movement.

AA Cup type very soft flow nozzle with low pressure higher volume design.

AA Fabric drive reel with Frequency controller.

Specifications & Dimension are subject to change without any prior notice.

|

Capacity (Kgs.) |

Chamber |

Length (mm) |

Height (mm) |

Width (mm) |

|

300 |

2 |

4300 |

3600 |

3050 |

|

450 |

3 |

4300 |

3600 |

3675 |

|

600 |

4 |

4300 |

3600 |

4300 |

|

750 |

5 |

4300 |

3600 |

5000 |

|

900 |

6 |

4300 |

3600 |

5650 |

Versatile Solutions for the Textile Industry

With a broad range of capacities and customization options, these dyeing machines are compatible with a wide variety of fabric types and widths. Their stainless steel construction ensures durability and resistance to corrosion, making them ideal for demanding textile processing operations. High energy efficiency and low noise operation create a more sustainable and comfortable working environment.

Advanced Automation and Safety

Automatic PLC or digital controls allow for precise operation and reduce the need for manual intervention. Safety features include high-temperature protection and pressure relief valves, safeguarding both operators and textiles. The thermally insulated outer shell maintains optimal temperatures while minimizing energy consumption, further enhancing safety and efficiency.

Comprehensive Service and Support

From installation and training to ongoing maintenance, comprehensive after-sales services are provided across India. Whether you are a manufacturer, distributor, or service provider, expert support ensures the machine integrates smoothly into your workflow, maximizing productivity and longevity for your textile operations.

FAQ's of Atmospheric Soft Flow Dyeing Machines:

Q: How does the Atmospheric Soft Flow Dyeing Machine ensure gentle fabric treatment?

A: The machine uses a perforated soft flow drum and integrates adjustable speed controls, enabling delicate handling of both woven and knitted fabrics. This design ensures even dye penetration without damaging textile fibers, making it suitable for high-quality dyeing, scouring, bleaching, and washing processes.Q: What are the main advantages of its stainless steel 304/316 construction?

A: Stainless steel 304/316 provides robust corrosion resistance and longevity, even when exposed to harsh chemicals and high process temperatures up to 98C. This construction ensures reliable performance and easy cleaning, extending the machine's operational life.Q: When should atmospheric soft flow dyeing machines be used instead of high pressure alternatives?

A: These machines are ideal for temperature-sensitive processes and fabrics that do not require high-pressure dyeing. Their atmospheric operation is perfect for standard dyeing, scouring, and bleaching applications on a range of textile materials, with a maximum temperature just below boiling point.Q: Where can these machines be implemented and who benefits most from them?

A: Atmospheric soft flow dyeing machines are suited for textile factories, fabric dyeing units, and processing facilities across India. Manufacturers, exporters, wholesalers, and service providers handling woven and knitted fabrics benefit from their efficiency and capacity scalability.Q: What safety features are integrated in this machine?

A: Safety is prioritized through high temperature protection systems and a pressure relief valve. Additionally, the engine's noise level is kept below 72 dB, and the outer shell is thermally insulated to protect operators from heat exposure.Q: How does the PLC/digital control enhance operational efficiency?

A: PLC and automatic digital control panels allow operators to set and monitor process parameters precisely. Features like auto dosing and programmable cycles reduce manual intervention, guarantee consistent dye results, and streamline workflow.Q: What after-sales services are included with this machine purchase?

A: Customers receive comprehensive after-sales support, including professional installation, operator training, and ongoing maintenance services. This ensures maximum uptime and efficient integration into your production lines throughout India.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'Fabric Dyeing Machine' category

|

APEX ENGINEERS

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |