Eco Logical Fabric Jet Dyeing Machine

500000.00 - 5000000.00 INR

Product Details:

- Fabric width 500 mm - 3200 mm

- Control Type Automatic PLC Control

- Speed Variable speed (frequency controlled)

- Power 10-50 kW

- Voltage 220-440 Volt (v)

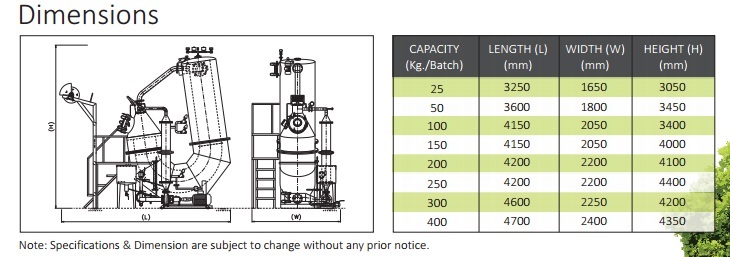

- Dimension (L*W*H) Customized (based on capacity and chambers)

- Type Eco Logical Fabric Jet Dyeing Machine

- Click to View more

X

Eco Logical Fabric Jet Dyeing Machine Price And Quantity

- 500000.00 - 5000000.00 INR

- 1 Unit

Eco Logical Fabric Jet Dyeing Machine Product Specifications

- 220-440 Volt (v)

- 10-50 kW

- Customized (based on capacity and chambers)

- 500 mm - 3200 mm

- Variable speed (frequency controlled)

- Automatic PLC Control

- Metal

- Cotton, Polyester, Blends, Silk, Wool

- Eco Logical Fabric Jet Dyeing Machine

- Textile fabric dyeing, Suitable for woven/knitted fabrics

- 1-6 Chambers (customizable)

- High Pressure Stainless Steel Jet Pump

- Low liquor ratio, Eco-friendly, Energy efficient, Robust construction, Stainless steel body, Corrosion resistant

- 1000-20000 Kilograms (kg)

- 2024

- Up to 140C

- 50 kg - 1200 kg per batch

- Up to 1800 Liters

- Horizontal / Vertical Jet Dyeing

Eco Logical Fabric Jet Dyeing Machine Trade Information

- Cheque

- Per Month

- 2 Week

- All India

Product Description

Eco Logical Fabric Jet Dyeing Machine

Complete with Dye Kitchen & Accessories

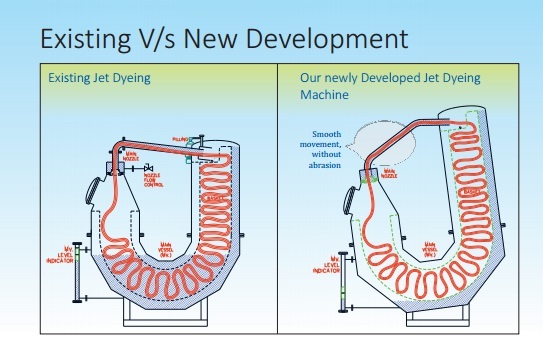

In our (Bhagyarekha) latest development we are reducing the liquor ratio its also reduce the thermic energy and chemical consumption.

In these new development we reduce the fabric lifting jeight its give smooth fabric movement with out entanglement.

Another main benefit that we increase the dye bath contact area of fabric for better color presentation and good dyeing result.

Benefits

- liquor ratio less then existing "U" type jet dyeing machine.

- Reduce thermic energy

- Reduce chemical Consumption.

- Reduce power consumption compared with existing "U" type jet dyeing machine.

- No need of pilling

- Lowest running cost.

- Zero Entanglement.

- Low fabric lifting height.

Eco-Friendly Performance

Engineered with sustainability in mind, this jet dyeing machine minimizes water consumption and optimizes chemical use through its advanced, programmable dosing system. Its low liquor ratio design not only conserves resources but also lowers operational costs, making it an ideal choice for environmentally conscious textile facilities.

Versatile Fabric Compatibility

The machine is highly adaptable, able to process a diverse range of woven and knitted fabrics such as cotton, polyester, blends, silk, and wool. Its customizable chamber options and variable speed settings ensure precise handling for different fabric widths and types, maximizing dyeing quality and fabric integrity.

Robust Construction and Safety

Constructed from premium Stainless Steel 304/316L, this dyeing machine boasts enhanced durability and corrosion resistance. Integrated safety features-including over-temperature and pressure protection, emergency shut-off, and automated drainage-prioritize operator safety and equipment longevity.

FAQ's of Eco Logical Fabric Jet Dyeing Machine:

Q: How does the Eco Logical Fabric Jet Dyeing Machine reduce water and chemical consumption?

A: The machine incorporates a low liquor ratio system and automated programmable dosing to deliver precise amounts of water and chemicals, significantly minimizing consumption and waste during each dyeing cycle.Q: What safety features are included with this jet dyeing machine?

A: Safety is ensured by built-in over temperature and over pressure protection, a dedicated emergency shut-off system, and an automatic drainage system with filtration, all designed to protect both operators and the machine.Q: When should the machine's maintenance be performed and how easy is it to service?

A: Maintenance is required periodically depending on usage, but the machine's low-maintenance design and easily accessible panels make routine servicing straightforward and efficient, minimizing downtime.Q: Where can this fabric jet dyeing machine be installed?

A: The machine can be installed in any textile processing facility, with customized dimensions and configurations to accommodate different space and production requirements. It is suitable for textile dealers, manufacturers, exporters, and other industry stakeholders.Q: What types of fabrics and capacities can the machine handle?

A: It efficiently processes a wide spectrum of fabrics-cotton, polyester, blends, silk, and wool. Capacities range from 50 kg up to 1200 kg per batch, and it can be tailored with 1 to 6 chambers to suit varying production needs.Q: How does the color touch screen interface benefit operators?

A: The intuitive color touch screen enables simplified machine operation, real-time monitoring, and easy access to automatic PLC control settings, enhancing workflow efficiency and reducing operator training time.Q: What are the advantages of using indirect steam or electrical heating in this system?

A: Both indirect steam and electrical heating provide consistent temperature control up to 140C, improving dye uniformity and fabric quality while maximizing safety and energy efficiency.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

|

APEX ENGINEERS

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |