Dyeing Machine Automation

Product Details:

- Fabric Type Cotton, Polyester, Blended fabrics

- Control Type PLC Based

- No Of Chamber Single/Multiple

- Voltage 220-440 Volt (v)

- Dimension (L*W*H) Customized

- Temperature Range Room temperature to 140C

- Usage & Applications Textile dyeing, Yarn dyeing, Fabric processing

- Click to View more

Dyeing Machine Automation Price And Quantity

- 1 Unit

- 500000.00 - 5000000.00 INR

Dyeing Machine Automation Product Specifications

- 2023

- Energy efficient, User friendly interface, Accurate process control, Corrosion resistant

- 500-5000 L

- Centrifugal

- Up to 2400 mm

- 50-1000 kg per batch

- Metal

- Variable

- 500-40000 Kilograms (kg)

- 7.5-30 kW

- Dyeing Machine Automation

- Automatic

- Textile dyeing, Yarn dyeing, Fabric processing

- 220-440 Volt (v)

- Single/Multiple

- Customized

- Room temperature to 140C

- Cotton, Polyester, Blended fabrics

- PLC Based

Dyeing Machine Automation Trade Information

- 3-4 Unit Per Month

- 2 Week

- Western Europe, Australia, Eastern Europe, Middle East, Central America, Africa, South America, Asia, North America

- All India

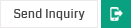

Product Description

Our immense domain expertise and market knowledge assist us manufacture, export and supply the finest quality array of Dyeing Machine Automation. The offered automation is used for controlling the rate of rise and fall during the process of thermoregulation in dyeing machine. This automation is precisely manufactured in compliance with international standards by making use of prime quality raw material. The offered Dyeing Machine Automation is rigorously tested on certain parameters to ensure its excellent functionality.

Features:

-

Operational fluency

-

Trouble free functionality

-

Sturdy construction

-

Longer service life

-

Time temperature profile (ramp& soak) for controlling the rate of rise & fall during thermoregulation also hold time

-

Automatic operation of heating ,cooling, pressurization and depressurization

-

Feather touch keypad for easy operation and flexible programming

-

25 recipe with 16 step each can be permanently stored

-

Seven segment display.

Programmer for Dyeing Machine for Partly Automatic Operation

Programmer for Dyeing Machine for Partly Automatic Operation is ideally used for automatic operation of the main vessel. These programmers are designed and developed by engineers as per universally accepted norms, which elaborate in their user-friendly interface and convenient operations. The range of programmers has 16*2 LCD display that shows message commands in simple English language. An additional benefit of these programmers is that these increase the working efficiency of machine, hence optimizing dyeing energy as well as time.Exclusive Features :

-

Suitable for automatic operation of the main vessel (only main vessel or kier)

-

Automatic function of filling main vessel drain main vessel &rinsing using level switches

-

Time temperature profile (ramp& soak)for controlling the rate of rise & fall during thermoregulation also hold time

-

Pressurization& depressurization of main vessel (kier)

-

Operator call with message (load, unload, check ph prepare tank, add chemicals, add dyes etc)

-

16*2 lcd display with simple english message command for easy understanding for operator

-

1rtd +8 digital input +8 digital output(standard configuration) expandable to 32 di & 32 do

-

35 recipe of 99 step each can be permanently stored

-

2 analog input card can be expanded (4 to 20 ma ) for level transmitter instead of level switches (optional)

-

2 analog output card can be expanded (0 to 10vdc or 4 to 20 ma ) for pump & inside winch speed control (optional)

-

Separate individual card for digital input, digital output and expandable analog input & analog output

-

Special card for filling main vessel with flow meter for precipice batching of water (optional).

Programmer for Dyeing Machine for Fully Automatic Operation

Programmers for Dyeing Machine for Fully Automatic Operation eliminate any kind of manual error related to the dyeing process. These easy-to-operate programmers are suitable to be installed in dyeing machines as the production capacity is significantly increased by their fully automatic mechanism. In addition to this, these products display temperature, time, gradient and others on 20*4 LCD screen that can be easily be understood by the operator. Programmers also have 4 analog input cards that can be expanded up to 4 to 20 ma, as per the end users' specific requirements.Exclusive Features :

-

Suitable for automatic operation of the main vessel (only main vessel or kier) as well as color tanks

-

Automatic function of filling main vessel drain main vessel &rinsing using level switches

-

Automatic function of color tank like fill ct, drain ct, mv to ct, ct to mv(inject ct) ,dosing ct etc.

-

Time temperature profile (ramp& soak)for controlling the rate of rise & fall during thermoregulation also hold time

-

Pressurization& depressurization of main vessel (kier)

-

Operator call with message (load, unload, check ph prepare tank, add chemicals, add dyes etc)

-

20*4 lcd display with simple english message command for easy understanding for operator

-

1rtd +8 digital input +16 digital output(standard configuration) expandable to 64 di&64do

-

35 recipe of 99 step each can be permanently stored

-

4analog input card can be expanded (4 to 20 ma ) for level transmitter instead of level switches (optional)

-

4analog output card can be expanded (0 to 10vdc or 4 to 20 ma ) for pump & inside winch speed control(optional)

-

Separate individual card for digital inputs, digital outputs and expandable analog inputs & analog outputs

-

Special card for filling main vessel with flow meter for precipice batching of water (optional).

Controller for Dyeing Machine Control

Controllers for Dyeing Machine Control are equipped with robust operating system, ideal for industrial applications. These controllers use parallel programming, which results in the reduced process time. Advanced panels of these controllers have separate mcbs, inverter, choke, spacious panel and several excellent features, thus, enhancing their efficiency. Besides, for safety purposes, these controllers are equipped with limit switches, separate pressure switches, air inlet pressure failure alarm, stand-by extra temperature controller and alarms for over pressure as well as over temperature.Exclusive Features :

-

Touch screen controllers with windows ce : robust operating system tailored for industrial applications sedo-treepoint (make)

-

Reducing the process time by using parallel programming instead of sequential programming

-

Logging of temperature curve,functions,alarms & visualization of process on controller

-

Support of multi language more then 10

-

Internet technology(integrated web server) for remote access from any pc in the plant network via microsoft internet explorer

-

USB interface : for in expensive devices like memory keys (copy/save programs) and other pc peripherals

-

Ethernet tcp/ip network :link to central system & other dye house system(optional)

-

Storage of a virtually unlimited number of dyeing programs

-

Possible to integration with chemical dispensing &dye kitchen (optional)

-

Also can provide mini or central supervisory& monitoring system for multiple machine as per customer requirements (optional)

-

In the filling process keeping the liquor ratio constant for the whole batch using electromagnetic flow meter and differential pressure type level transmitter

-

Exact temp gradient control using modulating control valves with electronuematic positioner

-

Programmable automated dosing of dyes & chemicals with different curves (linear, progressive °ressive)

-

Also possible under ht condition (using metering pump ,inverter &analog level sensor) (optional)

-

Differential pressure control using main pump inverter& dp pressure sensor (optional)

-

Seam detector for seam catching ,cycle time study & circulation control (optional)

-

Rinsing different type (counter,time,interval,oscillation) as per use requirement

-

3 different fill valve (soft, cold ,hot) & 3 drain user selectable

-

Jet washing system for washing main vessel (kier) without filling the whole vessel gives good amount of water &energy saving

-

Adding 1 stock tank+ 1additional tank can reduce the process time & energy with parallel programming function (optional)

-

Power drain for fast draining of the main vessel(kier) using main pump(optional)

-

Combined rinsing & cooling facility for main vessel (optional)

-

On line ph-tds indication & control system(optional)

Panel Features :

-

Separate mcbs for all motor & control

-

Separate inverter for mainpump, inside winch, platting, dosing etc.

-

Separate choke for each inverter

-

Spacious panel for easy working and maintaining

-

All electrical accessories standard make

-

Schneider make (switchgears, mcbs, pushbuttons, selector switches),

-

Lapp make (power cable & screen cable ,lugs)

-

Phoenix make (connectors)

-

Honeywell make (control relays &limit switches)

-

Hensel make (pushbutton stations)

-

Control transformer for 230 vac control

-

2 separate 24vdc smps for plc and other controls

-

Inside winch & main pump speed indicator on the main push button station with speed control facility for easy operation for the operator

-

Led indicators for all valves and motors for easy diagnosis of its on / off

-

Entanglement annunciating device by monitoring the inside winch motor current continuously and giving an alarm in abnormal condition

-

Limit switches for filter& door

-

Separate pressure switches for overpressure alarm depressurization of main vessel(kier)

-

Air inlet pressure failure alarm

-

Stand by extra temperature controller

-

On operation possible in pressurization mode that can create any hazard to operator or staff

-

Tower lamp for indication of operator call, alarm, running for operator visible from distance

-

Over pressure alarms hotter

-

Over temperature alarms

State-of-the-Art Automation for Dyeing Processes

The dyeing machine automation system is engineered for high performance in modern textile operations. Its PLC-based control ensures accurate and reliable process management, while the variable speed drive and user-friendly touch screen interface provide flexibility for different fabric types and batch sizes. Robust construction and safety features complement its innovative design.

Versatile Dyeing Applications

Suitable for various fabrics including cotton, polyester, and blends, this automatic dyeing solution accommodates different batch capacities and widths up to 2400 mm. It serves textile dyeing, yarn dyeing, and fabric processing, catering to manufacturers, exporters, wholesalers, and other industry players across India.

Energy and Water Efficient Operation

Optimized for low water ratio processes and equipped with energy-saving technology, the dyeing machine helps reduce operational costs. Stainless steel construction, corrosion resistance, and an efficient centrifugal pump system further enhance sustainability and reliability during continuous use.

FAQ's of Dyeing Machine Automation:

Q: How does the touch screen HMI improve the operation of the dyeing machine automation system?

A: The touch screen HMI provides an intuitive user interface, allowing operators to easily configure, monitor, and manage various parameters such as temperature, speed, and batch settings. This reduces manual intervention, minimizes errors, and enhances overall process control.Q: What are the benefits of the fully automatic, PLC-based control system in this machine?

A: The fully automatic, PLC-based control system delivers precise and consistent dyeing results by automating process variables and maintaining optimal conditions throughout the cycle. It also enables data logging for process traceability and ongoing quality management.Q: When should I choose this dyeing machine automation system for my facility?

A: This system is ideal when you require high efficiency, accurate control, and scalability for textile, yarn, or fabric dyeing operations. It's suitable for facilities needing batch capacities from 50 to 1000 kg and fabrics up to 2400 mm wide.Q: Where is installation service available for this dyeing machine automation system?

A: Installation services for this dyeing machine are available across India, ensuring professional setup and commissioning by qualified technicians, regardless of the customer's location.Q: What safety features are included to ensure operator and equipment protection?

A: The machine is equipped with essential safety features such as over-temperature protection and an emergency stop button. These safeguards help prevent accidents and protect both the operator and equipment during operation.Q: How does the low water ratio design benefit textile dyeing operations?

A: The low water ratio design reduces water consumption drastically, making the dyeing process more environmentally sustainable and cost-effective while still achieving uniform and high-quality fabric coloration.Q: What materials of construction make this machine suitable for industrial use?

A: Fabricated from high-grade stainless steel 304/316, the machine offers excellent corrosion resistance and durability. This ensures longevity, even in demanding industrial environments handling a variety of textile chemicals and processes.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'Fabric Dyeing Machine' category

|

APEX ENGINEERS

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |