Ht. Hp. YARN DYEING MACHINE ( CONEX )

350000.00 - 3500000.00 INR/Set

Product Details:

- Type Yarn dyeing machine

- Voltage 5 TO 50 Horsepower (HP)

- Manufacturing Year 8 Years

- Power 415 Volt (v)

- Dimension (L*W*H) AS PER MACHINE CAPACITY Millimeter (mm)

- Weight 200 - 3500 Kilograms (kg)

- Speed TURBO SPEED mm/m

- Click to View more

X

Ht. Hp. YARN DYEING MACHINE ( CONEX ) Price And Quantity

- 350000.00 - 3500000.00 INR/Set

- 1 Set

Ht. Hp. YARN DYEING MACHINE ( CONEX ) Product Specifications

- 8 Years

- 5 TO 50 Horsepower (HP)

- Yarn dyeing machine

- TURBO SPEED mm/m

- ALL KIND OF YARN

- 200 - 3500 Kilograms (kg)

- AS PER MACHINE CAPACITY Millimeter (mm)

- 415 Volt (v)

Ht. Hp. YARN DYEING MACHINE ( CONEX ) Trade Information

- SACHIN

- Letter of Credit at Sight (Sight L/C), Cheque

- 4 Set Per Month

- 1 Months

- Contact us for information regarding our sample policy

- PLASTIC WRAP

- All India

- WE ARE ISO 9001: 2015 CERTIFIED

Product Description

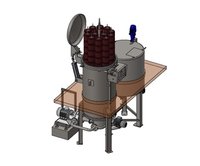

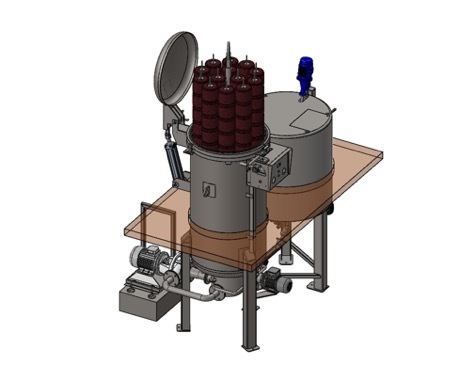

HTHP Vertical Yarn Dyeing Machine (Conex) is one of our best selling machines since its introduction. Precision engineered High Temperature High Pressure Vertical Yarn Dyeing Machine has become the first choice of dyeing plant throughout the Textile Dyeing Industry. HTHP Vertical Yarn Dyeing Machine (Conex) has been designed for dyeing Polyester, Cotton, Viscose, Nylon, Acrylic, Texturised, Silk, Wool & all natural and manmade fibers in various forms like Cone, Tape, Narrow Fabrics, Zipper, Hanks, Ribbons, Tops & Loose Fiber. These machines are offered for capacities from 10 kg up to 1000 kg. per batch.Â

Versatile Yarn Dyeing Capabilities

This machine expertly accommodates a wide array of yarn types, making it suitable for businesses that handle diverse textile projects. The capacity and specifications are adjustable, ensuring efficiency in both small and large-scale operations across the fabric industry.

Enhanced Productivity with Turbo Speed

Engineered for turbo-speed dyeing, the Ht. Hp. Yarn Dyeing Machine drastically reduces process times. Its advanced design allows for rapid and consistent coloring, optimizing output without sacrificing dye quality or uniformity.

Reliable for Industrial Use

With eight years of proven manufacturing quality, this yarn dyeing machine combines durability with state-of-the-art technology. It is ideal for heavy-duty, continuous operation, meeting the needs of importers, exporters, and manufacturers alike.

FAQ's of Ht. Hp. YARN DYEING MACHINE ( CONEX ):

Q: How does the Ht. Hp. YARN DYEING MACHINE (CONEX) enhance the dyeing process?

A: The machine utilizes turbo-speed technology for faster processing times and uniform dye distribution, improving both productivity and product consistency across all kinds of yarn.Q: What types of yarn can be processed with this machine?

A: This model is specifically designed to handle all kinds of yarn, supporting the diverse requirements of textile producers and processors.Q: When should I consider using this dyeing machine for my operations?

A: If your operations demand fast turnaround, large batch capacities, or involve a variety of yarn types, this machine's robust build and adjustable specifications make it a suitable choice.Q: Where is the Ht. Hp. YARN DYEING MACHINE (CONEX) typically used?

A: This machine is widely employed in textile manufacturing units, yarn processing factories, and dyeing workshops across India by suppliers, exporters, service providers, and wholesalers.Q: What is the usage process for this yarn dyeing machine?

A: Operators load the yarn, configure settings based on batch size and fiber type, and initiate the automated dyeing cycle. The machine handles the coloring, rinsing, and drying processes efficiently.Q: What are the main benefits of using this yarn dyeing machine?

A: Key benefits include decreased production time, better dye penetration, flexibility for various yarns, and energy-efficient operation due to its capacity and power options.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

|

APEX ENGINEERS

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |