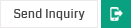

HTHP Dyeing Machine

Product Details:

- Control Type PLC-based automatic control

- Type HTHP Dyeing Machine

- Capacity Up to 1000 kg per batch

- Weight 500-40000 Kilograms (kg)

- Fabric Type Woven, Knitted, Synthetic & Natural Fabrics

- Voltage 220-440 Volt (v)

- Power 10-150 kW

- Click to View more

HTHP Dyeing Machine Price And Quantity

- 500000.00 - 5000000.00 INR

- 1 Unit

HTHP Dyeing Machine Product Specifications

- HTHP Dyeing Machine

- PLC-based automatic control

- Up to 1000 kg per batch

- 500-40000 Kilograms (kg)

- Woven, Knitted, Synthetic & Natural Fabrics

- 220-440 Volt (v)

- 10-150 kW

- Centrifugal / High efficiency

- Metal

- Up to 2000 L

- Up to 3200 mm

- 1-4 (depends on configuration)

- Automatic

- Customized as per model

- Industrial fabric dyeing, Laboratory dyeing, Sample and bulk production

- Up to 140C

- 2024

- Low liquor ratio, Energy efficient, Robust construction, Uniform dyeing

- Variable

HTHP Dyeing Machine Trade Information

- Cheque

- 3-4 Unit Per Month

- 2 Week

- Western Europe, Australia, South America, Eastern Europe, Middle East, Central America, Africa, Asia, North America

- All India

Product Description

Fostered with a team of highly experienced professionals, we have been able to manufacture, export and supply HTHP Dyeing Machine. This machine is specially designed to dyeing heavy and sensitive fabrics like terry towel, curtain bed sheet of 100% cotton knit and woven fabrics. Machine able to work as a soft / over flow with minor adjustment, offered machine is precisely engineered under the guidance of our seasoned professionals by employing rotating magnetic field and excellent quality raw material. Our valuable clients can avail this HTHP Dyeing Machine in different specifications at industry leading price.

Features:

- Excellent functionality

- Accurate result

- Strong construction

- Operational fluency

Exclusive Features:

- Lowest Liquor ratio

- Lowest Energy consumption

- Lowest thermic energy

- Reduce Maintenance

- Lowest Running cost

- Zero Entanglement

Technical Features:

- Capacity 25kg. To 2000kg.

- Process have & sensitive fabrics like Terry Towel, curtain, bed sheet, 100% cotton knit and woven etc.

- Work as a Soft Flow as well as over flow dyeing.

- High temp. - up to 140 C

- Vessel made from Stainless Steel SS 316 L.

- Specially design filtration system.

- Provide sheet inside the chamber for smooth fabric movement.

- Higher Volume, Low pressure soft nozzle with larger diameter for heavy and larger width fabrics.

- Fabric drive reel with frequency controller.

Optional Features:

- Fully Automatic with PLC

- Flow Meter (Water liter counter)

- Main Motor Inverter

- Seam Detector

- Magnetic Level Indicator/Controller

- Pre-heating tank with accessories

Advanced Efficiency and Uniform Dyeing

Engineered for optimal efficiency, the HTHP Dyeing Machine boasts a low liquor ratio and high-grade insulation, leading to significant reductions in water and energy usage. The automatic chemical and dye dosing system ensures consistency and color uniformity across each batch. PLC-based controls further streamline operations and help minimize manual intervention.

Comprehensive Safety and Control Features

Safety mechanisms such as pressure relief valves, emergency stop functions, and automatic temperature cut-off provide operators with peace of mind. The mirror polished inner surface reduces fabric abrasion, while thick mineral wool insulation keeps noise levels below 70 dB and improves energy efficiency. Variable speed and high-efficiency pumping allow precise control for different fabric types.

Versatile Application and Customization

With capacities up to 1000 kg per batch and up to four configurable chambers, this machine fits both large-scale industrial settings and precise laboratory needs. It supports a range of voltages and can be tailored in dimensions. Its automatic operation and robust reliability make it ideal for manufacturers, exporters, dealers, and service providers across India.

FAQ's of HTHP Dyeing Machine:

Q: How does the HTHP Dyeing Machine ensure uniform dye distribution?

A: Uniform dyeing is achieved through a combination of centrifugal or high-efficiency pumps, automatic chemical and dye dosing, and a mirror-polished inner drum surface. Together, these features ensure consistent chemical flow and minimize fabric distortion during the dyeing process.Q: What safety features are integrated into the HTHP Dyeing Machine?

A: The machine is equipped with multiple safety mechanisms, including a pressure relief valve, automatic temperature cut-off, and an emergency stop system. These features protect both operators and equipment from potential hazards such as overpressure or overheating.Q: When can industries benefit from using this dyeing machine?

A: Industries can utilize the HTHP Dyeing Machine for both routine bulk production and specialized laboratory dyeing. Its adaptability to processing various fabric types and batch sizes makes it beneficial throughout textile manufacturing cycles, from sample development to large-scale operations.Q: Where is the HTHP Dyeing Machine typically installed?

A: This machine is ideal for textile mills, dyeing houses, R&D labs, and production facilities that handle woven, knitted, synthetic, or natural fabrics. With customizable dimensions, it can be installed in diverse industrial environments across India.Q: What is the process for operating the HTHP Dyeing Machine?

A: The process involves loading the fabric, setting parameters on the PLC-based controller, and adding chemicals via the automatic dosing system. The centrifugal pump circulates dye liquor efficiently, while precise control of temperature and pressure ensures optimal dye absorption across different fabric types.Q: What are the benefits of the machine's low water usage design?

A: With a low liquor ratio and efficient water management, the machine conserves resources, reduces effluent treatment costs, and minimizes environmental impact. This feature is especially valuable in regions with water scarcity or strict environmental regulations.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'Fabric Dyeing Machine' category

|

APEX ENGINEERS

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |